What steam power and generative AI have in common

They foreshadow(ed) big changes to come, but further innovation is (was) required to increase reliability and lower costs

Welcome back! Today we are talking about farmers. This is the first of a series of case studies of the history of technology disruption in a particular occupation. If you missed the introductory chapter that explained why looking at the past will help us predict the future of work with AI, you can read it here. If you read it already – thanks for sticking around!

Farming is the canonical example of technology-driven labor market disruption. Everyone knows that we used to be an agrarian economy, and now we are not. Recall from last week’s figure that about half of U.S. employment was in farming in the late 1800s, but today it is less than two percent, and still declining.

Technology obliterated agricultural employment because it relaxed an important bottleneck in the food production process - power. If you want to figure which jobs are next, don’t ask what some new technology is capable of, ask what problem it will solve.

What problems are being solved by generative AI? As I discuss below, we have seen impressive productivity gains in a variety of white-collar jobs for workers using chatGPT and other LLMs. But the scale of those productivity gains is probably not large enough (yet) to disrupt work. More importantly, generative AI is still too unreliable and expensive.

As it turns out, AI has a lot in common with steam power, which improved productivity in a range of jobs and clearly foreshadowed the major changes that were to come. Still, steam-powered machines that could automate farm work were available for more than 100 years before it actually happened. Complementary innovation was required, and I suspect that will be true as well with generative AI.

Power - the escape from subsistence farming

Despite what you may have heard, farming is probably the world’s oldest profession. Domestication of plants and animals began at least ten thousand years ago. For most of this time, agriculture was about survival rather than employment. People grew crops and herded animals to feed themselves and their families, not to sell to others. Even today, roughly a fifth of the world’s population engages in subsistence farming, and it was still common in the U.S. as late as the early to mid 1900s.

In farming, the difference between subsistence and gainful employment is mostly a matter of scale. Once you grow more than you can eat, you sell the rest. What prevented farmers from scaling for most of human history? Not arable land, which was plentiful. The key bottleneck in farming was power – the limited endurance of human beings. People can only generate so much power before they tire out. Power depends on strength and fitness, which in turn depends on health and nutrition. Power also declines with age, as my children are fond of telling me, which explains why subsistence farming was almost always a family affair.

Power was especially important for ploughing, the practice of loosening and turning soil to bring nutrients to the surface to prepare it for seeding or planting. Ploughing alone accounts for about 60% of the total energy requirements for growing wheat, according to one estimate. Ploughing is grueling work, especially when you only have two legs, so farmers had to “employ” a lot of horses and mules. These beasts of burden helped relax the power constraint, but they brought their own scaling limitations. They require care and feeding, and like people their endurance is not unlimited.

An obvious candidate to replace horsepower was steam power. The U.S. Industrial Revolution was well afoot by the early 1800s. Steam engines were supplying huge amounts of power to textile mills, iron foundries, steamboats, and railroads across the country. In 1712 Thomas Newcomen invented the first practical steam engine, which enabled the pumping of water out of mines. It worked by heating water to create steam that pushed a piston up, and then cooling the steam to bring it back down. Newcomen’s design was made more efficient by James Watt, who began selling the Watt engine to manufacturers in the 1770s, and soon the steam engine was everywhere.

And yet in 1920, 200 years after the first functional steam engine was developed, there were still more than 25 million horses and mules on American farms, about four per farm. This isn’t because nobody thought of using steam power for farming. Steam engines for ploughing were first developed in the 1830s. By the 1870s, steam traction engines that could be driven without horses were being sold in the U.S., and in 1890 George Edwards filed a patent for a “tractor to be propelled by steam-engine.”1 Yet as late as 1900, only a few thousand steam tractors were produced and sold in the U.S. each year.

If steam engines were revolutionizing heavy industry in the 1800s, why did it take so long to automate farm work?

The tractor – a general-purpose power supply

One reason is that early mechanized ploughing and threshing machines were lumbering beasts that weighed over 30,000 pounds. They were dangerous to operate and broke down easily. Most importantly, they were far too expensive for small independent farmers, who preferred the versatility and reliability of horsepower.

Steam power was available for other farm machinery like threshers, reapers, and combines. But these machines needed to be pulled by something. Even if you could afford a steam-powered thresher, and the technology was reliable, the cost savings were limited if you still had to “employ” draft animals to pull them. The economics only made sense if you could remove animal labor from the picture entirely.

The unreliability and cost of the steam tractor was still a productivity bottleneck, because the cost savings per unit of horsepower weren’t high enough to make farmers give up their animals.

Tractors were a great invention. But the big leap forward was the addition of a gasoline-powered internal combustion engine, which was much more practical than steam for mobile machines like tractors. While the first gas-powered tractors were large and expensive, producers quickly adapted to meet market demand. In 1917 Henry Ford released the “Fordson”, a smaller, cheaper, and more reliable alternative to earlier models like the Case gas tractor, shown below:

The Fordson, pictured below, weighed only a few thousand pounds and cost under $1000. By 1923, Fordson had 77% of the U.S. market. Annual production rose from about 6,000 in 1918 to 99,000 by 1926.

The Fordson was cheap and reliable, but equally importantly, it was general-purpose. Ford and its competitors like Deere and Case quickly realized that a lighter and more maneuverable tractor could perform a wide variety of farm tasks. Competition between companies for the tractor market unleashed many small improvements like rubber tires, power lifts, and the three-point hitch, which continuously leveled uneven ground as it ploughed. A “dominant design” for tractors emerged in the late 1930s, and tractor production peaked in the United States around 1950.

The tractor-fueled productivity miracle

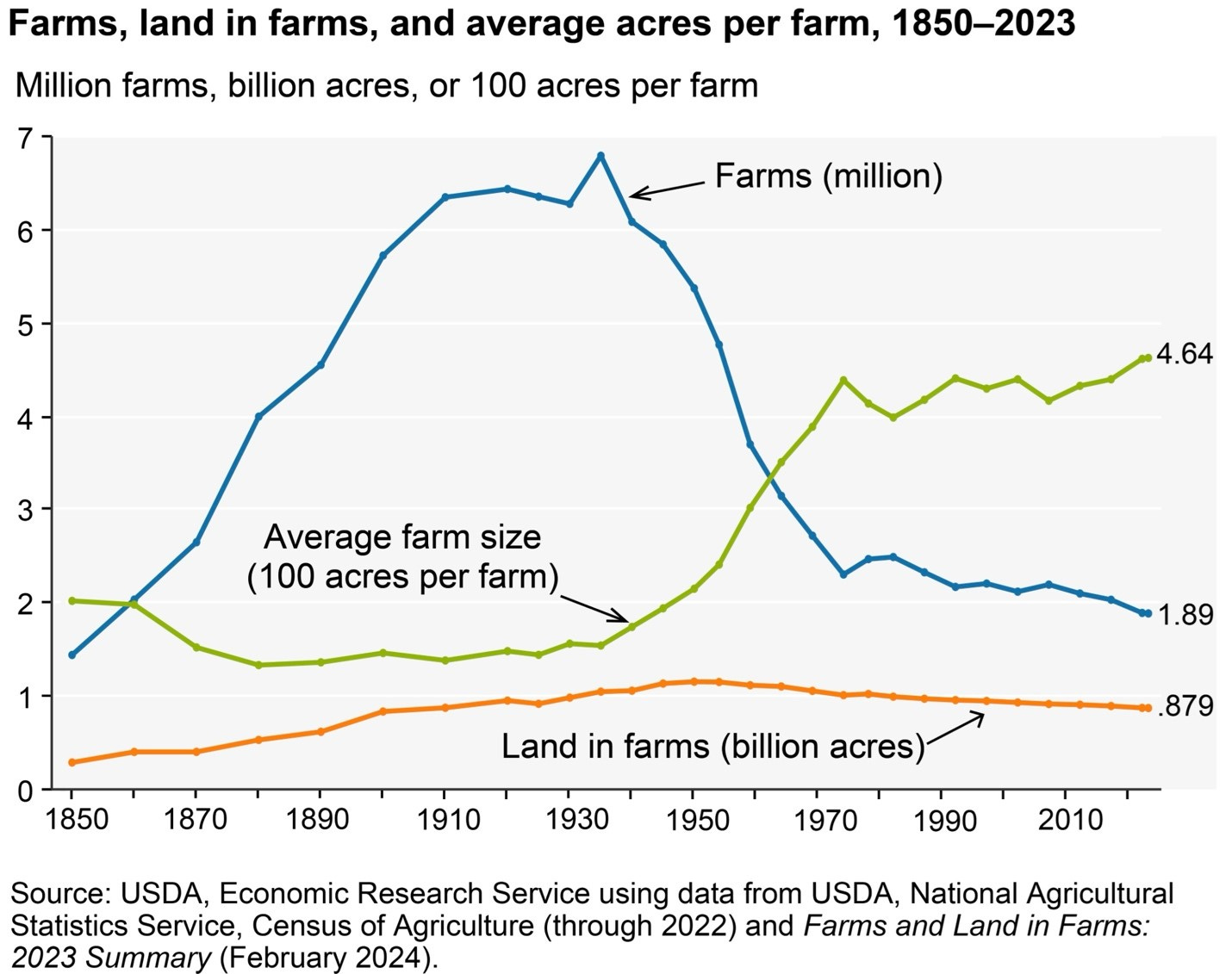

Continuous improvement in tractor quality coincided with the rapid mechanization of U.S. agriculture. Between 1930 and 1960, the share of U.S. employment in farming fell from 20 percent to 6 percent. Horse and mule “employment” in farming declined from nearly 20 million to less than 3 million. And the number of farms dropped by half, from more than 6.5 million to just over 3 million.

And yet, total U.S. agricultural output increased substantially between 1930 and 1960, and output per hour of human labor increased fourfold. The reason is scale. As the figure below shows, average farm size nearly tripled over this period, while the amount acreage devoted to farming stayed the same. Farmers were getting greater crop yield out of the same land, with substantially lower human and animal labor costs.

Today, fewer than two percent of all workers are employed in farming. The remaining workers are of two types. First are the farm owners, who are relatively well-off. In 2022, the median income of farm households was $95,418, compared to an overall U.S. median of $74,580. Those operating large farms are extremely wealthy, with a median household income of $505,833. They are running large, capital-intensive operations and have more in common with managers and business owners than with the farmers of the early 1900s.

The other type of farm workers are in “last mile” jobs, the part that can’t be automated. These are typically poor seasonal migrant workers, often unauthorized. The USDA estimates that about half of hired crop farmworkers are unauthorized migrants and about 70% are foreign-born. However, the number of unauthorized immigrants living in the U.S. peaked in 2007, which has increased pressure to automate the farm work that remains.

For cereal grains like wheat and barley, power was the major bottleneck. For fruits and other delicate crops, the bottleneck is precision. Humans have excellent fine motor skills, and the ability to quickly judge when fruit is blemish-free and ripe enough to be picked and eaten. We take these skills for granted, but they are cognitively complex, and difficult to teach to a machine. That’s why fruit harvesting was still quite labor-intensive throughout the 20th century and remains so today.

Yet computer vision and remote sensing technology is rapidly making it possible to automate blueberry harvesting and strawberry picking, leading to declining seasonal employment in places like Maine. These “last mile” jobs may be diminished further or even eliminated by AI.

What does productivity improvement in agriculture tell us about AI?

Mechanization disrupted farm employment because it relieved the most important production bottleneck – power. When farming without machines, humans and draft animals were expensive to maintain and tired out quickly, which limited a farmer’s ability to scale. Steam engines relieved the power constraint but were costly and unreliable. Two complementary innovations – the internal combustion engine and the general-purpose tractor – were required to fully unlock productivity growth in agriculture.

The best case for generative AI is an analogy between physical power and brain power. Frontier generative AI models arguably provide you with a highly intelligent research assistant whose brain never gets tired. Is that enough to disrupt knowledge work?

Several recent studies randomize access to ChatGPT and find that generative AI boosts productivity by around 20 to 25 percent in a broad range of white-collar jobs and tasks – coding for software developers, professional writing for office jobs, customer service, and management consulting.

A 20-25 percent productivity increase is impressive! However, by comparison, labor productivity in U.S. agriculture grew by about 300 percent between 1930 and 1960. Do you think there is any job in which ChatGPT could make a competent professional four times more productive?

Generative AI is still relatively new, of course, and improvements are surely on the horizon. But don’t forget that the 20-25 percent figure applies to particular tasks, not an entire job, so it needs to be scaled down by the share of tasks assisted by AI. We need to also factor in the high energy and compute cost of generative AI usage, and the issues with hallucinations and unreliability.

Generative AI is to office jobs what steam power was to farming. A promising technology on the horizon that already provides a modest productivity boost across a wide range of jobs and tasks, but is too costly and unreliable to create disruptive change without further complementary innovations (aka a killer app).

The word “tractor” is a portmanteau of “traction” and “motor”. It appeared first in this patent but was also coined independently by a salesman trying to squeeze ad copy into fewer characters. I grew up in smallish towns on the outskirts of Nashville and LOVED tractors when I was a kid. It took a lot of self-discipline for me to relegate this to a footnote rather than boring you with a long digression on the history of tractors

Steam tractors were very heavy so they used steel wheels which were narrow resulting in high ground pressure making steam tractors useful only in places with hard soils. The solution was the caterpillar continuous track but it appeared at a time when ICE already doomed small steam engines. An interesting what if is what if the caterpillar track was invented in the 1850's. Imagine Civil War pics with tracked steam vehicles pulling heavy artillery and supply wagons.

There's a range of occupations: farming grain versus truck farming; dairy farming, ranching; fishing, aquaculture, floriculture--etc. The tractor impacted grain and cotton production earlier and more greatly than the other areas.